Key points of power cable crimping process-preparation stage

2013-01-21

1. Preparation phase

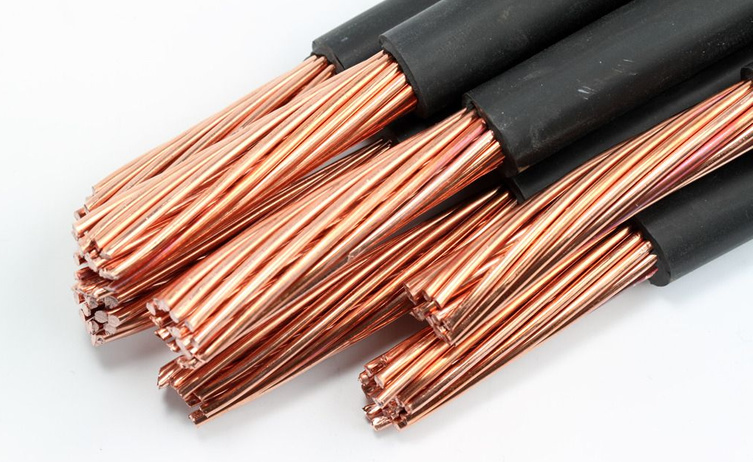

1) Check and check the model and specification of the connection fittings and die, which should be consistent with the nominal section of the connected cable conductor, the type of conductor structure (tight or non-tight) and the hardness of the conductor.

2) Stripping off the insulation at the end of the connected wire and cable. The length of stripping off the insulation is generally the length from the end of the connecting pipe to the cut-off pit or oil blocking grid plus 5~10mm unless otherwise specified in the design. The length of stripping off the insulation of the terminal (wire nose) is the length of the conductor that can be inserted into the cylinder part of the terminal plus 5~10mm.

3) If the inner wall of the aluminum connecting pipe or terminal cylinder is not pre-coated with conductive grease, the inner wall should be wiped with cotton cloth dipped with clean gasoline, then the oxide film on the inner wall of the pipe should be wiped off with metal sandpaper, and then a thin layer of conductive grease should be evenly coated. The inner wall of the copper pipe shall be provided with a tin-plated layer, and contamination of the inner wall shall be prohibited in the future.

4) Circle the fan-shaped conductive wire core with carp tongs (round core is not necessary), tie the ends of the conductive wire core with copper wire as binding wire, and then file them flush. Then scrub the oil stains on the surface of the conductive wire core with cotton cloth dipped with gasoline, and brush the surface of the conductive wire core with a fine wire brush. In case of oil-paper cable, the conductor core shall be untied first, and then the core shall be brushed after the single conductor and the impregnant in the gap, and finally the conductive grease shall be applied.

5) Insert the conductor wire core into the connecting pipe or terminal cylinder. When connecting the middle of the cable, insert the conductive wire core into the center of the cut-off pit or connecting pipe. When connecting the terminal, it should be fully inserted into the terminal cylinder. For the intermediate connection of the three-core cable, the three cores of one cable shall be inserted respectively, and then the three cores of the other cable shall be inserted into the other end of the connecting pipe according to the phase correspondence.

Related News